Seeing your curtains sway gently in response to the afternoon breeze is a romantic word picture, like watching the house breathe. Until I tell you there’s a storm outside, and the windows are shut. The horrifying reality is that the cold wind is inside the house with you.

Here’s some simple fixes I’m making this winter to stop the chill from breaking in via poorly-insulated windows.

It doesn’t matter how many solar panels you have on the roof or the performance of the reverse-cycle system keeping you warm this winter, letting all that heat seep out the window is such a waste. If you don’t have a battery, it means you’re drawing from the grid to stave off the cold as soon as the sun goes down.

If you wan to keep your bills down, then efficiency is always king.

Windows Suck

Yes, yes I know there’s some benefit to having natural light and a sunny outlook to improve your mood, but windows seriously suck energy: roughly 40% of your heating is lost out through the glass in fact.

And they suck energy in across summer too, with windows accounting for around 87% heat gained when it’s hot outside.

A single pane of bare glass can gain or lose up to 10 times more heat than the same-sized area of uninsulated wall.

Here’s the thing though: builders in Australia have realised windows are cheaper than walls. A square meter of leaky alloy frame and 3mm glass doesn’t cost as much as timber, insulation and bricks.

Hence, we the public are marketed novelty oversized windows, for breathtaking views of your neighbour’s grey fence. Windows that go right up to the eaves are fantastic, because a steel lintel to support more bricks is another expense builders can avoid.

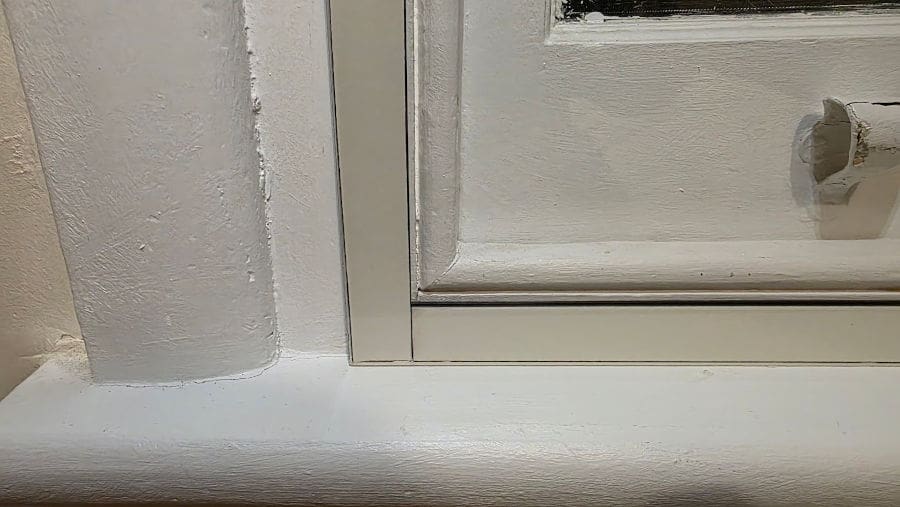

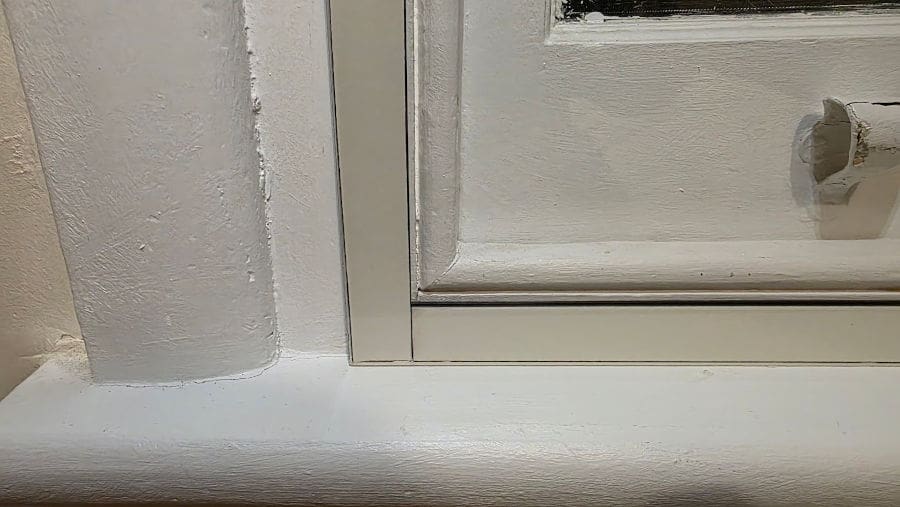

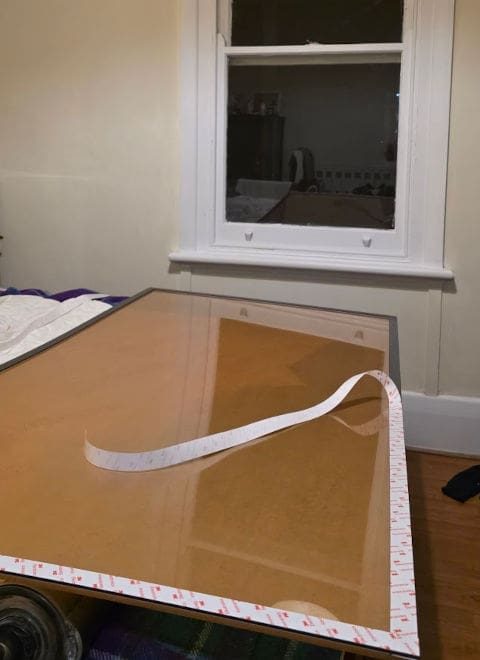

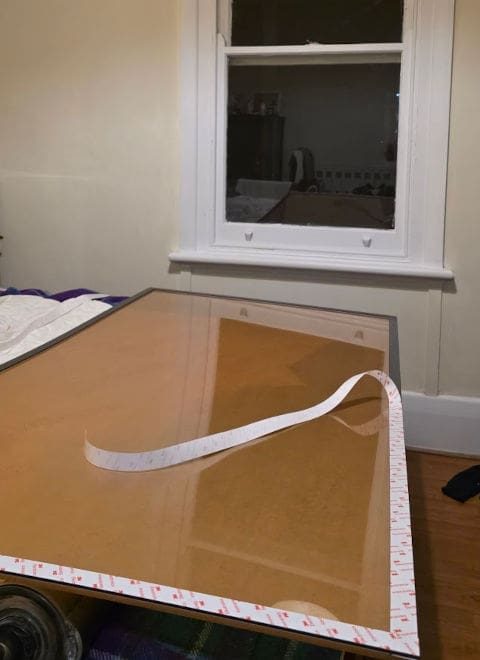

Secondary glazing is pretty unobtrusive.

Leaky Describes Two Problems

Firstly, there is seepage.

Aluminium is cheap for durable window frames and also makes great cookware because it’s a brilliant conductor of heat.

When heat seeps through material from your comfortable space to the outside of the house (or vice versa), housing efficiency jargon calls this a thermal bridge. Windows are a thermal superhighway, ably supported by steel or aluminium structure.

High-performance windows that have been available overseas for decades use either uPVC plastic or thermally broken metal frames, where the metal on the outside isn’t connected to the metal on the inside.

Gentle encouragement is sometimes needed to make things fit.

Secondly, there are drafts.

Most aluminium windows slide to open, and they are an inherently bad design. What passes for seals is just a brush or a bit of fluff. There are gaps top and bottom to make the sliding window easy to remove. While the track at the bottom for the rollers literally has vent holes in it.

This staggered window in the bog, like a fixed louvre, could never be closed until now.

Why? Well a poorly insulated house can often have condensation on the inside of the windows, so these channels are designed to collect water and drain it outside the house.

In other words. Australians build crap houses, and then just make holes to let the water out.

Wooden windows aren’t as bad.

In the age of carbon fibre, I refer to wood as the original carbon composite. Not only does it look lovely, it doesn’t conduct heat, so provided you can keep the weather off the frames, they really are better than aluminium.

However, wooden sash windows, the ones that slide up and down, they suffer the same sorts of leaks.

Old Style Comfort Control

Before air conditioning was a thing, people built houses with high ceilings simply to store a comfortable temperature while the heat of the day passed. Warm air could sit overhead and wait until the evening, when you could open the place up and flush it out.

Sash windows are so often painted shut, people don’t realise the top pane is supposed to slide down. I can assure you from first-hand experience, opening the bottom window does less than half the job. Opening both windows and letting heat out the top is three times as effective.

Sealing Sashes

Timber swells and shrinks with the weather, so sash windows need a little bit of clearance and maybe some wax to make them slide nicely. These gaps mean poorly made windows want playing cards jammed in them to prevent rattles, but even beautiful carpentry will leak a lot of air.

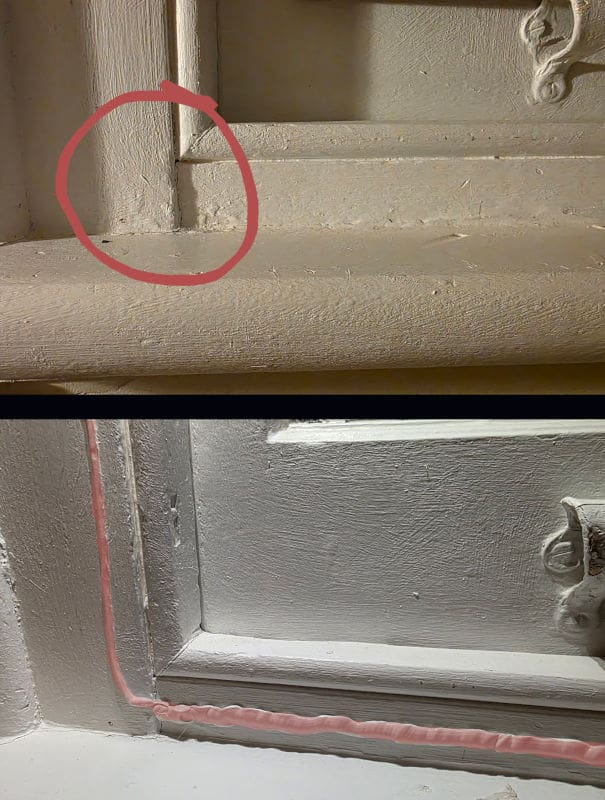

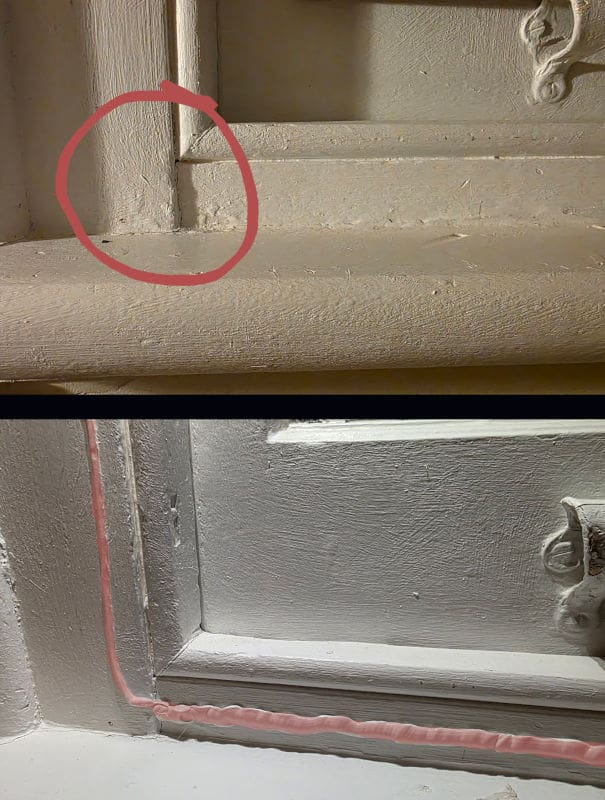

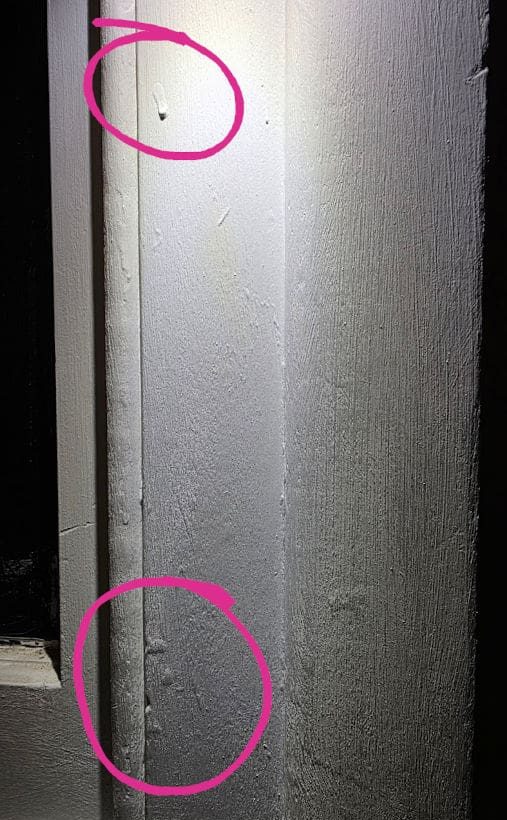

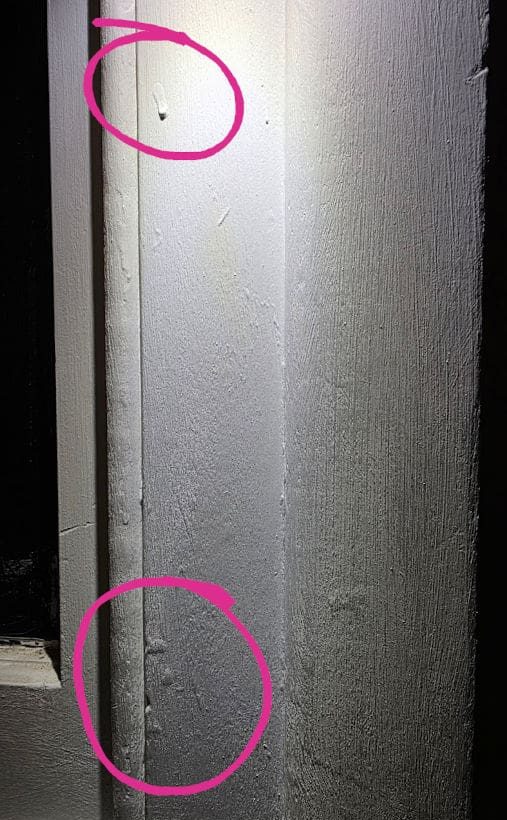

The step in this frame required filling with Sika 11FC sealant (highlighted) before the new pane and magnetic strip was offered up.

The internet doesn’t offer many detail shots of the finished product.

So while we’re going to install some new curtains and pelmets, I’ve set about using a slightly novel way to seal my sash windows using a single pane of 4.5mm perspex to stop the dreaded drafts.

Peel off the backing tape and get ready to stick the new pane in place, then remove the protective paper film.

Magnetic Magic

There are commercial suppliers of magnetically fixed secondary glazing. They arguably offer a more aesthetic finish with colour-coded edges, but it’s a little expensive.

I’m beginning to appreciate that the price isn’t too bad though, considering the effort involved in learning, measuring, ordering, transporting and installing.

Site supervisor was nonplussed by the accurately sawn edge of the plastic. This is easily sanded smooth if you’re so inclined.

For my project I started out measuring 13 openings and ordering material from Menzel Plastics. Be aware that some suppliers will score and snap sheets but better ones saw them down to size.

I’ve also ordered 30 metres of magnetic strip. Type A has a white foam backing, which I chose to stick onto the perspex so it roughly matches the colour of the window frames.

Turns out this foam backing would likely be better on the slightly uneven timber window frame. My first practice run shows the type B magnetic strip doesn’t conform much, so the adhesive doesn’t stick very well in some places. Sikaflex 11FC fixes that though.

These little lumps need to be shaved off or sanded down

Lessons Learnt

It looks so quick and simple on EweTube but I’m happy to report on the details which might bring you unstuck.

Perhaps the most important point I can make is this; assume nothing. There’s every chance your builder made the window sill crooked in relation to everything else.

The gap arrowed doesn’t appear at the bottom of the 1.6metre tall pane because the window sill isn’t straight.

- Measure top and bottom – your window opening might be tapered

- Give yourself clearance – 5mm per metre for thermal expansion

- Make doubly sure the surface is clean and free of lumpy or loose landlord-spec paint

- See that the frame you’re sticking to doesn’t have any steps

- Maybe order the more adhesive strip next time

- Trial fit your new pane before removing backing tape

– Check handles or locks will clear

– Make sure everything is square - You’ll only get one chance to stick the landing

– Mark the frame or add some guides if need be

Stay Tuned

I’m going to do a few more improvements around here with fettling a hot water service, fitting an induction cooktop, fixing French doors, sorting draughty chimneys plus other gaping holes in the fabric of this building.

For this episode, I’m pretty pleased. The results don’t look terrible, and the room is already much quieter. We’ll report back if there’s any problems with condensation, but for now this looks like a real winner.

For more on winter-proofing your house, read the earlier pieces in this series covering some general tips, and on how to properly maintain your reverse-cycle system.